Table of Content

In industries where equipment uptime is critical, unexpected breakdowns can lead to massive losses in both time and money. By combining Dynamics 365 with IoT (Internet of Things) telemetry data, companies can move from reactive maintenance to predictive strategies. This integration not only reduces downtime but also extends equipment life and improves safety.

At Skysoft Connections, we help businesses unlock the full potential of Microsoft technologies—such as Dynamics 365, Power Platform, and advanced IoT solutions—to create smarter workflows and reliable operations.

Why Predictive Maintenance Matters

Traditional maintenance approaches—such as reactive (fix when broken) or preventive (scheduled servicing)—often fail to address the real-time conditions of equipment. Predictive maintenance, powered by IoT and telemetry, changes this game.

- Reactive Maintenance → Costly and disruptive

- Preventive Maintenance → Not always efficient, may cause over-servicing

- Predictive Maintenance → Data-driven, real-time, and cost-effective

With telemetry sensors feeding data into Dynamics 365, organizations can predict when a machine is likely to fail and take action before it happens.

How Dynamics 365 & IoT Work Together

When integrated, Dynamics 365 and IoT create a connected ecosystem where data insights drive smarter decisions.

| Step | What Happens | Business Benefit |

|---|---|---|

| Telemetry Data Capture | IoT sensors monitor vibration, temperature, or pressure. | Real-time monitoring of equipment health |

| Data Processing | Information flows into Dynamics 365. | Centralized insights for quick action |

| AI & Predictive Models | Dynamics 365 AI analyzes trends and patterns. | Accurate failure predictions |

| Automated Alerts & Workflows | System sends alerts and creates work orders automatically. | Reduced downtime and faster response |

This connected workflow ensures that organizations stay one step ahead of equipment issues.

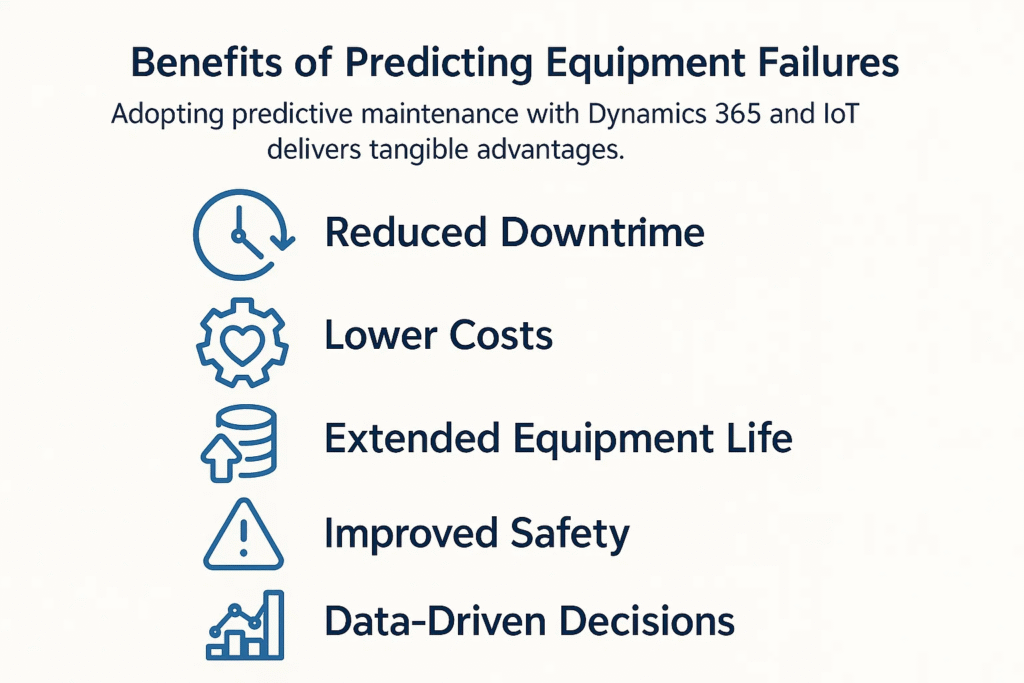

Benefits of Predicting Equipment Failures

Adopting predictive maintenance with Dynamics 365 and IoT delivers tangible advantages:

- Reduced Downtime: Address problems before they escalate.

- Lower Costs: Save money by avoiding unnecessary repairs and minimizing disruptions.

- Extended Equipment Life: Machines last longer with timely interventions.

- Improved Safety: Detect anomalies early to prevent hazardous situations.

- Data-Driven Decisions: Leaders gain insights for long-term planning.

Role of Skysoft Connections in Predictive Maintenance

At Skysoft Connections, we specialize in helping industries leverage Microsoft Dynamics 365, Power BI, and IoT to build predictive maintenance models tailored to their operations.

Our services include:

- Dynamics 365 CRM & ERP customization for seamless integration.

- IoT-enabled solutions that connect assets to centralized systems.

- AI-powered analytics to forecast failures and optimize resource usage.

- Power BI dashboards for easy-to-understand visual insights.

By combining our expertise with Microsoft’s tools, we make predictive maintenance simple, actionable, and cost-effective.

Real-World Example: Oil & Gas Industry

Imagine an offshore oil rig where equipment failures can cost millions of dollars per day. With IoT telemetry connected to Dynamics 365:

- Vibration sensors detect unusual patterns in drilling machinery.

- Dynamics 365 automatically generates a maintenance work order.

- Engineers receive alerts on mobile devices before a breakdown occurs.

- The company avoids costly downtime and ensures crew safety.

This is how predictive maintenance transforms industries from reactive firefighting to proactive problem-solving.

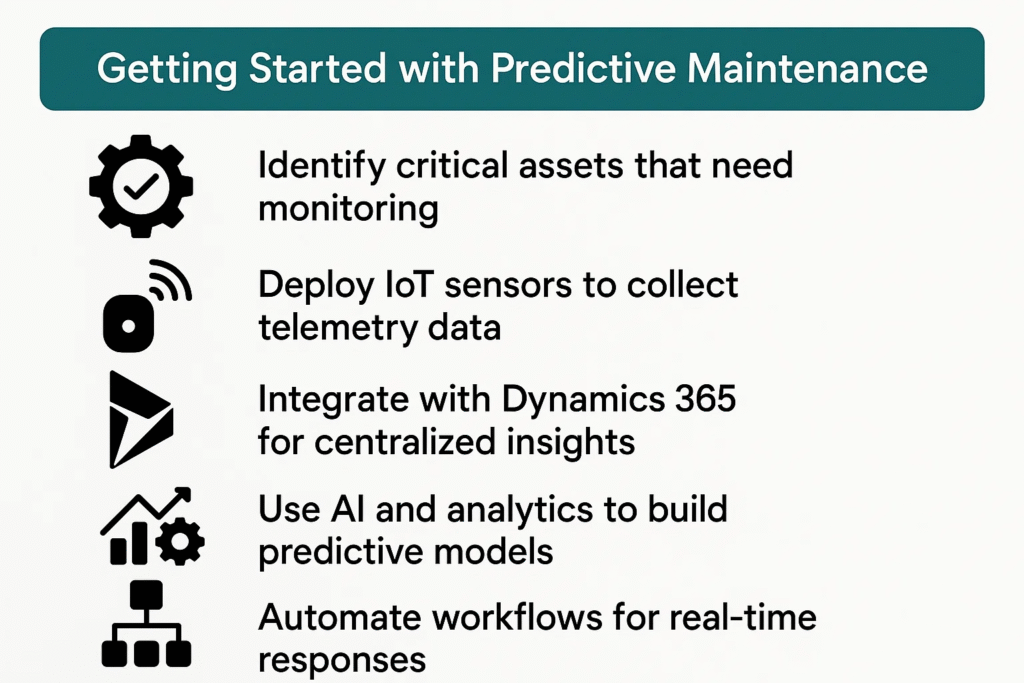

Getting Started with Predictive Maintenance

Implementing predictive maintenance doesn’t have to be overwhelming. Businesses can start small and scale gradually.

Steps to begin:

- Identify critical assets that need monitoring.

- Deploy IoT sensors to collect telemetry data.

- Integrate with Dynamics 365 for centralized insights.

- Use AI and analytics to build predictive models.

- Automate Workflows for real time responses

Conclusion

The future of maintenance lies in prediction, not reaction. By combining Dynamics 365 with IoT telemetry data, companies can ensure equipment reliability, safety, and efficiency.

At Skysoft Connections, we help organizations across industries embrace predictive maintenance with Microsoft technologies. From system integration to custom analytics dashboards, our solutions empower businesses to reduce downtime, cut costs, and work smarter.

Ready to future-proof your equipment?

Contact Skysoft Connections today and see how predictive maintenance can transform your business.

Read more : behavior based segmentation in dynamics crm

FAQ’s

Dynamics 365 collects real-time telemetry data from IoT sensors, analyzes it with AI models, and generates alerts or work orders before equipment failure happens.

Industries like oil & gas, manufacturing, utilities, and transportation benefit the most, as equipment downtime can cause major financial and safety risks.

Yes. Skysoft Connections designs tailored solutions using Dynamics 365, IoT, and Power BI to fit the unique needs of each business.

is a software solution company that was established in 2016. Our quality services begin with experience and end with dedication. Our directors have more than 15 years of IT experience to handle various projects successfully. Our dedicated teams are available to help our clients streamline their business processes, enhance their customer support, automate their day-to-day tasks, and provide software solutions tailored to their specific needs. We are experts in Dynamics 365 and Power Platform services, whether you need Dynamics 365 implementation, customization, integration, data migration, training, or ongoing support.

is a software solution company that was established in 2016. Our quality services begin with experience and end with dedication. Our directors have more than 15 years of IT experience to handle various projects successfully. Our dedicated teams are available to help our clients streamline their business processes, enhance their customer support, automate their day-to-day tasks, and provide software solutions tailored to their specific needs. We are experts in Dynamics 365 and Power Platform services, whether you need Dynamics 365 implementation, customization, integration, data migration, training, or ongoing support.